Category

- CNC Plasma Cutter

- Portable CNC Plasma

- Gantry CNC Plasma

- Table CNC Plasma

- Pipe CNC Plasma

- CNC Flame Cutter

- Portable CNC Flame Cutting

- Gantry CNC Flame Cutting

- Table CNC Flame Cutting

- Pipe CNC Flame Cutting

- CNC Laser Cutter

- Metal Sheet Cutter

- Portable CNC Cutting

- Gantry CNC Cutting

- Table CNC Cutting

- Metal Pipe Cutter

1000W CNC Laser Cutter Stainless Steel Sheet and Tube Cutting

Fiber laser cutting machine Description HS CODE: 8456110090 After-sales Service Provided:Onlinesupport, Field installati

Basic Info

| Model NO. | VLF 60M |

| Laser Technology | Laser Flame Cutting |

| Control System | Tube PRO |

| Laser Power | China Raycus 1000W |

| Pneumatic Parts | Japan SMC |

| Water Chiller | China S&a 1000 |

| Effect Cutting Area | 1000 mm |

| Reducer | Japan Shimpo |

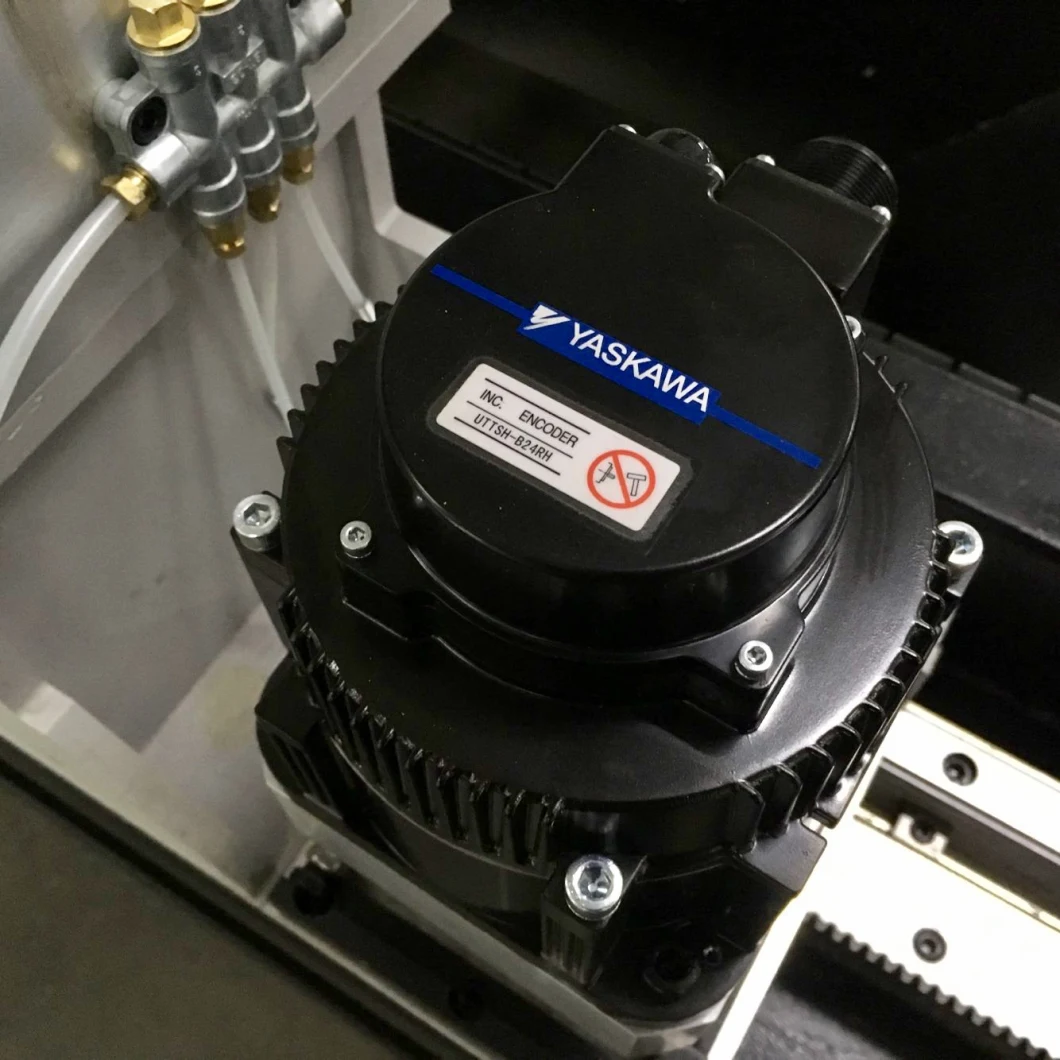

| Motor and Drive | Japan Yaskawa 2900W |

| Electronic Parts | France Schneider |

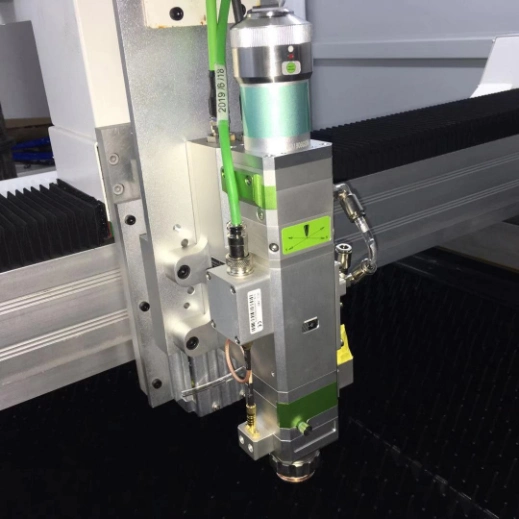

| Cutting Head | Raytools Bm109 |

| Rotary Length | 6m |

| Diameter of Rotary | 15-220mm |

| Transport Package | 40 Hq |

| Specification | 6000mm x220mm |

| Trademark | VMADE CNC |

| Origin | China |

| HS Code | 8456110090 |

| Production Capacity | 5000set/ Year |

Product Description

Fiber laser cutting machine DescriptionHS CODE: 8456110090

After-sales Service Provided:Onlinesupport, Field installation, commissioning and training, Field maintenance and repair service, Video technical support whole lifetime.

Applicable Material: Metal Industry

Laser Type:Fiber Laser

Laser Source Brand: China Raycus 1000W

Laser Head Brand: Switzerland Raytools Bm109

Servo Motor Brand:Japan Yaskawa Servo Motor and Driver

Rack and gear brand:Taiwan Apex

Key Selling Points:Multifunctional, High accuracy, Durability

Optical Lens Brand:Wavelength

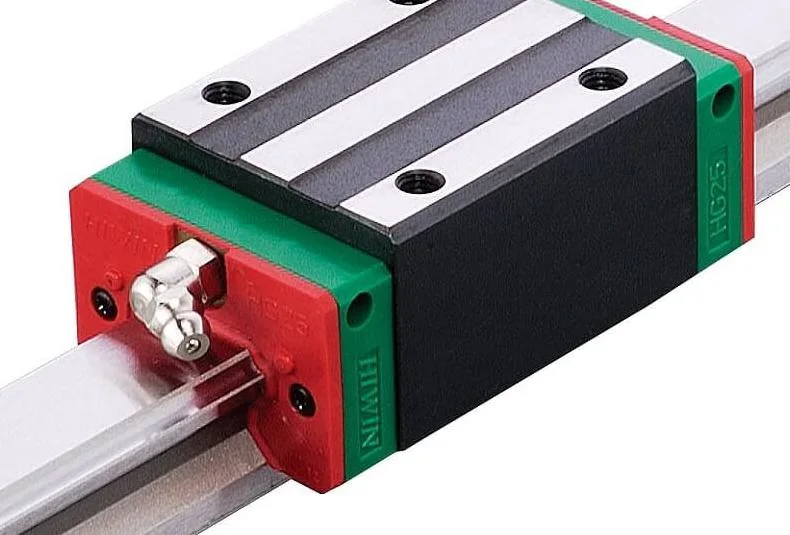

Guide rail:Taiwan Hiwin

Cutting Area: 6000mm

Machine Weight: 6.5tons

Max Speed, Max linkage speed(x,y):Max 100m/min

X Y axis max positioning speed : 120m/min

Cutting Thickness: Max 12 MM

Maximum acceleration:1.5G

Repositioning accuracy:±0.02mm

Graphic Format Supported:AI, DXF, PLT, BMP, DST, DWG, LAS, DXP

Applicable Industries:Building Material Shops, Machinery Repair Shops, Retail,

Construction works , Advertising Company

Condition:Brand New

Cooling Mode:Water Cooling

Control Software:Cypcut

Warranty:3 years on machine and laser (except Consumable parts)

Max loading weight: 800KG

Z Axis running range:290mm

Rotary length 3-6m , dia 220-300mm

Main Features of Fiber Laser VMADE CNC VLF 60M

(1) High photo-voltaic conversion rate (above 30%), which helps to save electricity and costs greatly to

guarantee the highest production efficiency.

(2) When processing, the laser only consumes electricity and doesn't need extra gas(only auxiliary gas ),

bringing the minimum operation and maintenance costs.

(3) Adopting semiconductor modular and redundancy design, without any optical glass in resonant cavity

and without start time, so it is in high stability and doesn't need adjusting and maintaining, which saves the

costs and time. In this point, the traditional laser is not comparable.

(4) The output wavelength of fiber laser is 1.06μm, which is a tenth of CO2 wavelength. The output beam is

in high quality and power density, so it is easy to be absorbed by metal materials and therefore has great

power to cut and weld to make the lowest processing costs.

Raycus Laser source |

|

Raytools head autofocus | The BM109 series are auto-focusing laser cutting heads released by RAYTOOLS AG in 2017 for fiber laser processing with 1.5kW or less. This products have a built-in motor drive unit, which drives the focusing lens through a linear mechanism to change position automatically within 17mm.Customers can set the program to achieve continuous focus that completing the rapid piercing and cutting material with different thickness. BM109 use the D28 diameters lense set to collimate and focus the laser beam, which can achieve the diffraction-limited optical effect. The design of water-cooled structure allows laser heads to work stably and chronically. |

Yaskawa servo motor and driver |

|

Tongfei Industrial Chiller | Using high-pressure electrostatic spray treatment, the appearance is elegant and unique, and durable. The control system adopts liquid crystal Chinese and English conversion computer controller, fully automatic control, simple and intuitive operation. With automatic fault diagnosis function, the fault point is directly displayed on the screen, prompting the user to process quickly. |

Taiwan guide rail | Hiwin linear slide rails are four-row single arc-arc contact linear slides, and integrate heavy-duty precision linear slides with optimized structural design to improve load and rigidity compared with other linear slides; It has four-direction load characteristics and automatic self-aligning function, which can absorb the assembly error of the mounting surface and obtain high-precision appeal. |

Cypcut visualized interface |

|

France Moto Reducer | The company is located in Saint-Etienne, a traditional military production base in Europe. It is created by cooperation between MOTOREDUCER and a well-known French military aerospace equipment manufacturing company through years of technical exchanges, global market analysis and strategic planning Highly demanding, higher standards and more comprehensive transmission equipment manufacturing enterprises. MOTOREDUCER planetary reducer has been promoted in the Chinese market since 2010, and has successfully served thousands of industrial equipment manufacturers in various fields. Now, in order to meet the improvement of the overall level of industrial manufacturing and better adhere to the "use technology to create value for the world" concept, in 2018 will launch a higher performance, more comprehensive RECKON-MOTOREDUCER precision planetary gearbox series products. |

Apex Rack and gear | These drives are perfect for a wide range of applications, including axis drives requiring precise positioning & repeatability, traveling gantries & columns, pick & place robots, CNC routers and material handling systems. Heavy load capacities and duty cycles can also be easily handled with these drives. Industries served include Material Handling, Automation, Automotive, Aerospace, Machine Tool and Robotics. The rack product range consists of metric pitches from module 1.0 to 16.0, with linear force capacities of up to 92,000 lb. Rack styles include helical, straight (spur), integrated and round. Rack lengths up to 3.00 meters are available standard, with unlimited travels lengths possible by mounting segments end-to-end. Quality levels available include soft, induction-hardened, quenched & tempered and hardened & ground (up to AGMA 12+ and DIN 4). |

Tips and Service kindly noted:

Delivery Detail:

Shipped in 15-20 working days after payment.Guarantee:3 years warranty for the whole machine. Within 24 months under normal use and maintenance, if something is wrong with the machine, you will get spare part for free.After 36 months, you will get spare parts at cost price. You will also get technical support and service all the lifetime 24h7d.

Technical support:

1. Technical support by phone, email or WhatsApp/Skype around the clock.2. Friendly English version manual and operation video CD disk.3. If needed, we can send our engineer to your site for training or you can send the operator to our factory for training.After sales services: Normal machine is properly adjusted before dispatch. You will be able to use the machine immediately after received machine. Besides, you will be able to get free training advice towards our machine in our factory. You will also get free suggestion and consultation, technical support and service by email/WhatsApp/tel etc.

FAQ for Laser Cutting Machine:

Q1: There are so many machine types, which one should I choose?

A: Vmade Laser provides machine parameters in each product demo page, please kindly check technical data column. It is important to compare all data before choose the best prototype. Also, our sales team provides online services to resolve your confusion, feel free to contact us.Q2: This is my first time buying your machine; I have no ideas about Vmade's machines quality?

A: Each machine is strictly produced based on the standard of ISO9000-2000, ISO14001-2004, GMC global manufacturer and CE certifications. Our products have CE certifications verified by TÜV SÜD, Bureau Veritas and etc. As china high-power laser cutting machine provider, more than 10,000 machines have been sold in the past ten years. Customer is our first priority. We are confident to tell customers that there is no need to worry about our quality.

Q3: When I got this machine, but I don't know how to use it. What should I do?

A:There are video and English manual with the machine. If you still have some doubts, we can talk by telephone or email.

For more information pls contact as below Sales Manager: Joseph Chao Website:vmadecnc.en.made-in-china.com Address: No.677 high-Tech Zone Shangdong province,China